Climate Change Cockup - Turns Out We Need Steel, CO2 And The Truth

Looks like Keir wants some steel for his theme park

Emergency Legislation To Save Scunthorpe Steel Plant

Keir Starmer announced emergency legislation on April 11, 2025, to safeguard British Steel’s Scunthorpe plant, a critical facility employing over 3,000 workers. Perhaps Kier now wants some steel for the new theme park!? Just now, after decades of decline suddenly we clock on and realise we need steel! This announcement is talking the talk, but will the walk be walked?

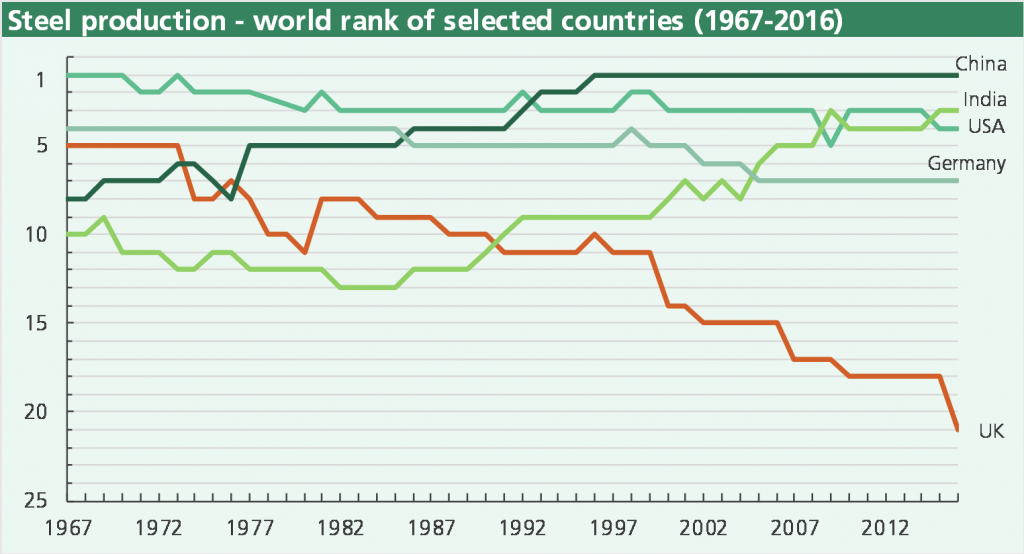

The UK Steel Industry Is In Trouble - Net Zero Is Massively To Blame

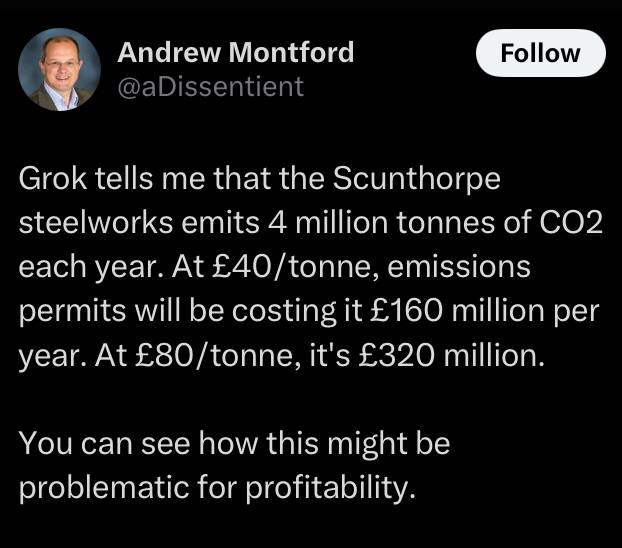

Scunthorpe’s plight is a symptom of deeper issues plaguing the steel sector. Crippling energy costs, among the highest in the developed world, have eroded the industry’s competitiveness. These costs stem directly from the UK’s net zero policies, which have driven up electricity prices through reliance on expensive renewables and the curtailment of domestic fossil fuel production. Compounding this are environmental regulations aimed at slashing CO2 emissions, which impose burdensome compliance costs on steelmakers. Far from being a necessary sacrifice, this anti-CO2 crusade is misguided. Carbon dioxide is a natural component of the atmosphere, vital for plant life and ecosystems, and its vilification rests on shaky scientific ground.

After the closure of the last blast furnace in Port Talbot, Wales, Scunthorpe remains the last steel plant of the only four left in the country that can produce steel.

A blast furnace is a huge industrial installation where iron ore, coke, a type of coal, and limestone are combined at extremely high temperatures (over 1,500°C) to produce liquid iron, also known as hot metal. This is then either cast into pig iron or refined further into steel through additional processes like a Basic Oxygen Furnace.

Why they matter:

They are the core of primary steelmaking — producing steel from raw materials (iron ore and coal).

Blast furnaces allow a country to make its own steel from scratch without relying on importing semi-finished steel products (like billets or slabs) from other countries.

They support heavy industries, defence, infrastructure, and strategic resilience.

If Scunthorpe’s blast furnaces shut:

The UK would no longer have any capability to produce primary steel from raw materials on its own soil.

The only remaining steel production would come from electric arc furnaces (EAFs), which recycle scrap steel rather than making it from iron ore.

EAFs can’t produce certain grades of steel needed for:

Large infrastructure projects

High-spec engineering applications

Defense and shipbuilding industries

Rail and some aerospace applications

Meaning:

The UK would become entirely dependent on imported semi-finished steel products from other countries like China, Turkey, or India for certain key steel grades.

This raises issues for national security, industrial sovereignty, and economic resilience.

Educating People On The Truth About CO2 Helps To Save Our Steel Industry

The Steel Industry Crisis Summed Up

Continue Your Learning

Climate Working Group Disbanded

Our enemies cannot handle a debate because the truth is too powerful. Instead, they do everything possible to silence opposition.

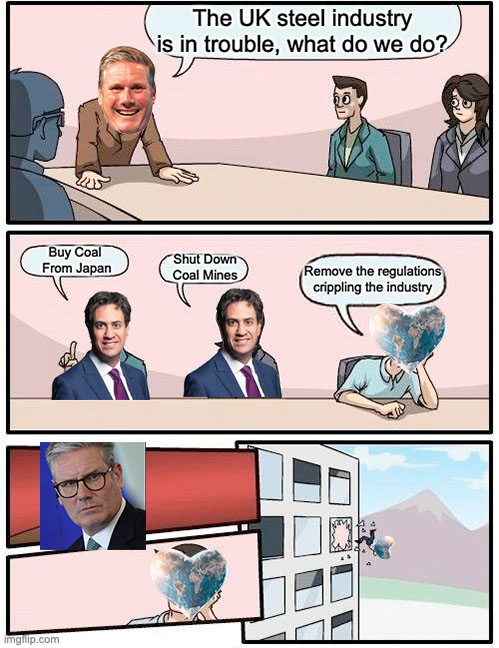

Net Zero Is Mathematically Impossible

Not only does net zero fail a logic test, it fails a maths test even more significantly. Numbers and facts don’t lie, no matter how loud the climate cult cry.

A Ridiculous Foray into Eco-Fantasy: The Vatican’s “Borgo Laudato Si” A New Climate Cult Centre

For some reason the pope is joining the ranks of the climate cult and is opening a new eco centre to supposedly inspire others to join the climate cult.

Net Zero Banking Alliance Defeated

The net zero banking alliance all but admits defeat as they pause operations and their future hangs in the balance of a members vote.

The Climate Is Always Changing And That’s A Good Thing

The climate is always changing and that is a good thing. I could adapt to it being a bit warmer in the UK quicktime, how about you?

Oil Rig Parts Maker Nearly Completely Abandons Operations Due To ‘cult of carbon’

The UK is getting left behind as the decimation of our industry continues under the banner of net zero. When we realise we don’t need any of this and claim our true abundant destiny?

Our Products

-

The Advanced Guide To The Climate Con Sigfned

The Advanced Guide To The Climate Con (Signed Hardcopy)

£32.99 -

Clothing

I Love CO2 Hoodie

£28.00 – £30.00 This product has multiple variants. The options may be chosen on the product page -

Accessories

No Digital ID Stickers – International

£3.50 – £4.00 This product has multiple variants. The options may be chosen on the product page -

Accessories

Chemtrail Awareness Sticker 1

£3.33 – £3.83 This product has multiple variants. The options may be chosen on the product page